The back-section

Back-section layout, cabin construction and furniture are mainly designed by us with some help of Alu-Star. The cabin is built by Alu-Star,

in Murg, Germany in superb quality.

Some of our "inventions" such as the bed, the table, the window lights are now

used in other back-sections built by Alu-Star.

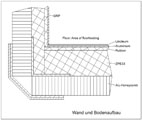

The construction of the cabin is based on a combination of aluminium-honeycomb, flexible ZPE-foam and GRP.

For an aluminium cabin it is very light and as such very well suited for campers of the 7.5 t category.

Aluminium as outer skin has been chosen mainly because of possible lightning strikes during thunderstorms and because of its UV-stability.

The cabin is mounted to a steel-frame that acts as a sub-chassis

between the truck and the back-section. The frame lays, isolated, directly on the chassis and is

bolted to the truck with 4 flexible hollow-rubber-spring supported mounts. This allows the cab to separate from the chassis should it twist off-road or on very uneven gravel roads. On good roads the whole setup is very stable allowing save high-speed driving up to 120 km/h.

Driver cab and back-section are two separate units. There is no escape door between the two. All necessary connections are plugged easily disconnectable. This makes it possible to lift the back-section off the truck if required (e.g. repairs, cleaning, shipment in a container).

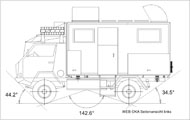

Outside view, Layout and technical diagrams of the camper back-section

Left, right and front view

Inside layout from top, the left side, the right side

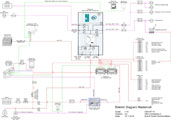

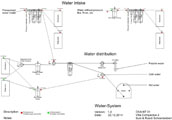

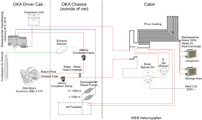

Electric, fresh-water and water-floor-heating system diagrams

Details of the camper back-section

The whole truck is quite small in size and very compact

taking into account its functionality.

It is 5.95 m long, 2.10 m wide and 3.12 m high. The track-width

is just marginally wider than the track-width of standard

3.5 t 4WDs (Landrover Defender 130).

The back-section is just 10 cm wider and a few cm longer

than the original OKA bus body.

The height however, is substantially higher than the

original OKA bus body to allow passengers to stand upright

in the camper.

Since the motor-home is designed to be used in very hot and very

cold areas (where temperatures fall to -20°C) a pop-top solution was unsuitable.

The inside of the back-section is 3.79 m long, 1.99 m wide

and 1.87 m high.

With hatches and window protection lids all closed

it looks more like a commercial truck.

This was done on purpose as there

are some countries where one doesn't want to be instantly recognised

as a tourist in a motor-home.

White was chosen as colour for the truck, not only because

of the heat reflection but also due to security reasons.

A light brown or green colour would have been better but the

truck could be mistaken as a military vehicle, which

is something we want to avoid.

The back-section has big fold-out windows on both sides and 2 skylights

in the roof to allow heat to

escape. There is no air-condition installed.

We should not go to places where we cannot stand the heat. If the A/C fails it may get dangerous.

Due to weight reasons standard Seitz Windows have been chosen. They can be locked at several angles.

While cruising the windows are covered by 2 mm aluminium lids for protection

against damage and for better security.

The lids also protect against sunlight and heat when

open while living in the camper and protect against branches and flying rocks when closed while

driving.

Windows and protective lids are both opened and closed

from inside the back-section.

To further improve the security on Roll-on Roll-off ferries the aluminium lids can be bolted to the back-section from inside the camper.

Easy attachable and removable cloth triangles can be fixed to the upper part of the door as well as to all windows. This allows us to let the upper part of the door and the windows open even if it rains. The feature is used mainly in hot and humid regions. If the coth triangles are not used the same fixation can be used on the door for a small clothes hanger which is also accessible from inside if the door is closed.

Opening the hatches shows all the hidden details.

The space in the front hatch on the left side is mostly taken

up by the water installation such as the 2 removable water tanks, filters and pumps.

It also houses the diesel stove. All is easy accessible in case of a repair.

The space in the back hatch is large and is subdivided.

The front section contains the "bicycle-garage",

housing 2 foldable city bicycles.

Cargo in the section behind the bicycles can be accessed

from both sides of the truck.

The water system is very flexible and can be "re-plumbed" to suit different requirements (see water system diagram above). The external connection is outside of the back-section. This allows to switch the system into city-water-mode with all hatches closed. All pressurised connections are based on the "Gardena" system, all vacuum connections are bolted.

The water tanks can be filled from sources with or without water pressure. In case we take water from a bore, river or lake, we insert the spare pump into the intake to suck in the water and to build up pressure to pass the sediment-filters.

Before reaching the tanks the water first passes a pressure reduction valve, then a coarse filter, followed

by 2 sediment filters. Since we later on also use a UV filter for water treatment we have to make sure the water is free of any particles which would else limit the UV-filters functionality.

The floor of the water management area has been fitted

with a stainless-steel basin with direct drain tubes to eliminate spilled fluids entering the back-section or its frame.

For water crossings all drains are fitted with Vacuators to eliminate water from entering the backsection.

Drinking water is stored in 2 x 100 litre steel tanks. 2 tanks have been chosen to prevent losing all potable water if we fill in water of bad quality.

Stainless-steel tanks were chosen to prevent the loss

of the water should the truck catch fire. The tanks have exits only at the top so the

tanks cannot leak.

The level of both freshwater tanks is monitored by water

gauges and the level is displayed on the "electric

panel" inside the back-section.

Potable running water is made available with a water

pump that has an internal water pressure regulator It takes the water from one of the two water tanks. Tank switching is done from inside the cabin.

The water then passes a carbon filter before branching

to the cold-water taps (sink, shower), to a UV-Filter with separate tap and to a 20-litre boiler followed by the hot-water taps (sink, shower).

Alternatively we can directly connect a city-water source. The water passes the same filters only bypassing the pump.

A silver wire is inserted in all warm water hoses between

the boiler and the tap to reduce the risk of bacteriological

re-contamination. The hot water can be heated by either

230V~ power from the inverter or external source, with hot water from

the motor's cooling system or the floor heating.

If we

are unable to get potable water,

we can fill one of the tanks with lower quality water (bore water) and switch the whole water installation into a 2-water quality system.

After "plumbing" our spare pump into the system and switching a y-tap, all water taps (sink, shower)

deliver

now

unfiltered cold and hot water of lower quality. Only the special tap after the UV-filter still delivers carbon- and UV-filtered potable water. As long as we can refill with bore water we will still have potable water for a very long time.

The Grey-water tanks holds 17-litres which is normally enough for one day. If we forget to drain it, it overflows to the outside.

The diesel driven stove has its own 7-litre fuel tank (not visible),

which is filled from the currently active main diesel tank by

an electric pump. The overflow is re-directed back into the same

diesel tank.

Having this small diesel tank inside the cabin also

prevents the diesel from gelling with cold outside temperatures.

At the same time the pump can be used to bleed the OKA's fuel system. It sits directly in front of the OKA's main diesel filter.

The 2 foldable city bikes are theft-proof stored and easy to be removed and stowed. Since they are stowed inside the camper they stay clean while driving.

A large table (126 x 71 cm) is also fitted

inside of the hatch lid.

4 people can comfortably eat at the table.

The section behind the bikes goes right through the back of the

truck and can be used for long items and stuff that must be accessible from both sides even if we tilt the truck, such as recovery gear and winch.

On the right hand side the hatch towards the front

contains the house battery, the inverter / battery-charger / transfer-system,

the solar controller, the B2B-loader and tools.

The hatch towards the back contains hand-winch, recovery gear,

tyre repair stuff, camping equipment, boogie boards and plastic (Rako) boxes

containing tools, fluids, spare parts, a.s.o.

At the rear of the front compartment is the shock mounted 360 Ah Lithium battery from Mastervolt. It is stored in a closed steel compartment with a drain hole to the outside. This should stop gas from entering the living room should we have a serious problem with the Battery.

In the front part of the hatch are repair tools in Rako-boxes. The space above is reserved for the electric installation. It contains most of the equipment from Mastervolt, the B2B-Loader from Votronic and some other bits and pieces.

The Mastervolt Ultra Combi has the following specs: Inverter 3000W permanent, main battery loader max. 150 A 12V=, second battery loader 12V= 10A, System input 230V~ max. 30A (normally reduced to 6 - 10A). The internal solar controller of the Ultra Combi is not used. It doesn't work with Lithium batteries.

The additional solar controller from Mastervolt can theoretically deliver up to 60A of load power. In the real world it delivers between 30 and 40 A out of 700W/12V solar panels.

The B2B-Loader charges the house battery with max. 45 A. Practical load is around 30 A.

The whole system is that good, that we normally cook with 230V~ power, heat our boiler electrically and still don't need external power. Of course, we also drive all our electric tools (chain-saw, drill, angle-grinder a.s.o.) with 230V~. Battery driven tool have the disadvantage that the battery pack is normally empty if one needs them.

The battery for the back-section is normally charged by 7 100W,

12V= solar panels mounted on the roof of the house.

The MPPT 60 solar controller can handle 60 Amperes. Excess power is discarded. Load current on a sunny day in Australia is between 30 and 40 Amps.

The panels are hinged and can be tilted for maintenance purposes.

Also mounted on the roof are the antennas for UHF CB-radio, 2 GPS, an Iridium Sat-phone and a Silentwind WiFi Web-Catcher.

GPS- and iridium antennas are protected

by a hinged Polycarbonate plate, the UHF antenne tilts back if hit by a branch.

Even so the antennas for GPS and Iridium should be water-tight, they must be mounted high enough above the roof so the cannot get drowned.

The hatch towards the back of the camper mainly holds the 3.2t manual winch, all of the other recovery gear, spare parts, and depending the trip grill, hiking gear and tent.

An expandable aluminium ladder which unfolds to 3.05

m in length is also stored here.

Its collapsed length is only 78 cm.

On the back of the back-section are

two 55W reversing lights and a reversing camera. Below that is a rack holding 8 reinforced fiberglass sandboards each 150 x 40 cm. With 8 boards one is able to build a road.

If the temperature gets too cold, a warm water under

floor heating system keeps the inside very cosy.

The main advantage of floor heating is that it avoids

the common "cold feet and hot head" feeling

typical of air heaters.

For weight reasons the heating tubes only run along the open floor and under the water tanks. That's not ideal because condensation in some areas is more difficult to control.

The heating is thermostat-controlled and driven by a warm water heater normally

used to pre-heat truck motors (Eberspaecher Hydronic M-II). The heating system is also connected to the warm water

boiler and via a water-water heat-exchange to OKA's motor cooling system. This allows

the floor-heating and the warm water boiler to be heated

with the OKA's motor cooling system using an additional circulation pump.

It also allows pre-heating of the motor in the morning

by using the warm water from the floor heating while using another circulation pump.

All this functionality can be switched by a single 6-position rotary switch operating a few relays. Another SUR invention.

The diesel heater is mounted in the OKA-Cab behind the co-driver seat and heats the inside of the cab overnight.

It takes the fuel from the left diesel tank which is also connected to the floor-heating to prevent the diesel from gelling on very low outside temperatures.

Floor heatings are great once they work right, but it needs some time to adjust it correctly. Best is to let them run 24 hours at the thermostat-controlled temperature, using the heater during the night and the motors cooling system during the day.

Floor heatings need a long time to heat up the room once it is cold. To speed things up we add an "Eberspaecher" Helios 2000 heater blower to the system. The water-air heat exchanger also uses the hot water of the floor heating as heat source and turns on automatically as soon as the water return temperature reaches 30°C. The heater blower is suited under the rear bench. The cold cab now reaches the set temperature within 4 minutes, but this is unfortunately too fast for the heater since it needs to run at least 10 minutes per cycle. To also achieve this requirement, we replaced the relay that turns on the blower by a time-delay-relay from Hella. It now starts 8 minutes after reaching 30°C.

To be able to use the diesel heating at higher altitudes we installed the "Eberspaecher" high altitude kit. The heating works without any troubles up to 3000 m. If one can make sure there is absolutely no exhaust gas in the combustion air intake the heating works up to 4300 m or even higher. It very much depends on the direction of the wind. No wind normally means it doesn't work.

Inside the back-section appliances and power outlets

are 12V= and 230V~. 230V~ appliances are, UV-water

purifier, hot water boiler (coolant or 230V~), microwave/grill/convection oven, induction cooking plate, fridge-box (230V~ or 12V=).

The 230V~ plug system used is the Swiss one. It is a

safer system than its Australian counterpart as the

power only flows once the plug is completely inserted

into the socket. The pins cannot be touched while pushing in the plug.

The circuit breakers for the 230V~ system

which also include RCD (residual current

devices), as well as the house battery isolator are anytime accessible from inside the back-section. All 12V= circuits are secured by proper circuit

breakers.

Funnily enough the system didn't get certified for

Australia because of the installed Swiss connectors

which are acceptable for tourists, but not for

residents.

It really doesn't matter as the campgrounds that should

check the certificate never do so. Beside that we don't

use powered sites anyway as we are normally fully self-sufficient.

All lights inside and the lights on the windows are dimmable LEDs.

The electric panel at the front of the back-section

contains from left to right:

- LED switch and dimmer for the kitchen light (underneath the panel)

- 12V= circuit breakers and switches

- 12V= plug (underneath the panel)

- 3 x 230V~ plug

(underneath the panel)

- iPod

- Mastervolt EasyView system monitor

- Control panel for the Wallas diesel stove

- Radio and Audio input connectors

- Watch

- Water tank level display and tank select switch

- Smoke detector (underneath the panel)

The sound system consists of a car stereo system driving

a 3-way speaker system. The system is remote controllable.

An USB interface allows the iPod to be connected

to the system. The 40+ GB MP3-files are our main

music source out bush.

The speaker cases are custom built.

There is a second interface in the driver's cabin thus

allowing the same iPod to be used in the back-section

and up front.

2018: This year ABC radio Australia stopped its transmission on shortwave radio so there is no more weather information available in the outback. We currently think about a satellite TV receiver which would overcome this problem.

The left image shows the "operators panel" beside the bed which consists of alarm system, alarm clock, remote control of theb radio and the dimmer for the LED light in the bed area.

There are various alarm systems in use.

Inside the back-section a narcotic gas alarm combined with

a CO alarm can be activated. The CO-sensor can be switched-off since some natural gases sometimes generate false alarms ;-))

An ultrasound intrusion detector in the OKA-cab is also connected to the central alarm system. Various door switches

and other sensors can be added to the system if needed.

A smoke detector is used inside the back-section during the night.

Another smoke detector is in the OKA-cab. It is activated if the diesel heater is in use. The same detector can also be mounted outside of the motorhome to protect against oncoming bush-fires.

Sleeping people don't smell smoke and don't notice an

approaching fire and therefore cannot react by escaping

on time.

The large windows are excellent for efficient ventilation

even with low wind. Besides that, they allow an excellent

view of the country outside.

There is no air condition installed in the back-section. To increase airflow in hot areas an additional, removable blower is installed. Even without the blower the temperature in the camper is always a few degrees cooler than outside due to the good overall insulation of the cabin, the window shutters and the solar panels on the roof.

Below the overheads are towel hangers installed.

The "Seitz" Windows have an integrated mozzie screen which unfortunately is not mozzie-proof. In addition, we use mozzie screens mounted with Velcro in a "cloth

frame". This allows easy replacement if damaged

and also allows different types of mozzie screens to

be fitted.

The cloth frame itself is also fixed to the window frame

using Velcro so it can be completely removed. The solution doesn't win a prize for its beauty but it works.

Due to weight reasons we install the well-known Seitz windows

even so we don't trust their durability. So far, the windows proofed to be much better as anticipated.

The pictures show from left to right:

- The open window without mozzie screen

- The closed window with the built-in mozzie screen closed

- The closed window with the blind half way closed (with the blinds closed no light can be seen from the outside which is a security measure)

- The closed window with

mozzie screen and blind halfway closed

- The closed window with our added, removable mozzie screen

- The red string used to unlock the window hatches.

LED stripes are fixed to all windows and to the upper part of the door. They shine from outside through the mozzie screens and spend enough light inside for living without turning on additional lights. Since the light source is outside the Camper the flying objects just fly to the mozzie screen and then turn around to reach the outside light. This enables us to always leave all windows open, no matter the amount of flying annoyances. Even better the ones already inside try to leave the camper to get to the LEDs.

The two 80 cm x 45 cm wide roof hatches consist of

an aluminium frame holding an 8 mm transparent polycarbonate

plate.

They are hinged on one side, can be fixed in 5 different

opening positions and can also be fully opened to give

access to the roof.

The tricky bit is to construct an opening mechanism that also holds the hatch in a stable, slightly open position of just 3 cm.

2016: To reduce the heat entering the living room during hot sunny days we give the "glass" a white half-transparent painting.

Added "splash walls" allow the hatches to be opened 3 cm under all weather conditions. No water or spray can enter under any weather condition.

Also inside the hatches there are hinged stainless steel

fly screens to protect against most of the well-known

"beasts".

If required Aluminium plates can be screwed inside the hatches

for better theft protection while the truck is on a

Ro-Ro ferry.

The mozzie screen door is a "can do everything"

gismo and was tricky to build. It must be 100% mozzie-proof.

It can be fully closed, fully opened as a fixed door or folded

away. When closed it can be locked from inside.

It can also be closed with the lower part

of the main door closed. In this case the mozzie screen door acts as an additional window at night.

The mesh used is of stainless steel and can be replaced.

The floor of the entry section is a 70 cm x 70 cm wide

shower pan, which also acts as a "wet and dirt"

entry area. An temporary mountable clothes hanger allowes wet clothes to be hanged above the shower pan.

The shower pan is only 3 cm deep and covered by a perforated

checker-plate aluminium sheet. The tray has 4 outlets, one

in each corner, thus allowing the water to drain even

if the truck is not level.

A 15 cm high side wall can be temporarily fitted to

prevent the shower curtain from moving outside the pan

when showering.

All cabinets consist of a very light aluminium frame reduced to the absolute minimum. As one can see the overhead compartment above only consists of the floor, the sidewall and the door (to be mounted). The aluminium L and U profiles used have a thickness of only 1.5.mm. The frames are very difficult to build and the welders from Alu-Star had to be top-notch to work with such thin materials and unstable structures. The walls are made of very light, only 5 mm thick GRP - Cardboard - GRP Honeycomb plates. Only when glued into the unstable frames it results in an amazingly sturdy furniture. Doors are made of 5 mm thick aluminium-plastic-aluminium sandwich plates (Alu-Cobond). We didn't use any wood in the whole motorhome

which is an advantage under humid conditions or when leaking water enters floor or walls. Under such conditions wood

would start to swell and rot.

The same sturdy fittings from Southco are used on all doors excluding the drawers of fridge and microwave due to their weight.

At the right side of the entry is a whole block of cabinets

(left side of the motorhome).

One cabinet on the top row holds clothes on hangers

and the other various household items

The middle cabinet was built for all our shoes.

The right bottom cabinet is used for various things

that have to be accessible from outside.

The other one hides the chemical toilet during the

day. During the night the toilet stands in the shower pan.

As the head part of the bed is behind the cabinet, there

is some minimal privacy when using the toilet during the night.

The bed in the back of the camper consists of a slatted

aluminium frame which collapses to half of its width

during daytime. The expanded bed measures 199 cm x 150

cm. It is possible to sit on the bed without hitting

the head on the roof.

The front border of the collapsed bed serves as upper part of the back rest of the long bench.

Collapsing and expanding the bed takes less than half

a minute.

Premium quality foam mattresses are used as well as

standard linen.

Very comfy!

Windows on both ends of the bed and a hatch above it

guarantee excellent ventilation.

Even if the bed is unfolded part of the table is still usable. Bench and table act as stair to access the bed.

Under the kitchen block there is the diesel tank for the Wallas diesel cooker, the wastewater tank, the UV-water purifier, the CO-fire extinguisher, the fire blanket and the 20l boiler. The area belongs to the "wet-area" and is fitted with a stainless-steel basin draining to the outside.

The kitchen is spacious because the different parts can be used

in several ways: for the stove, for the microwave, as work space, for

the drain board, etc.

We use different methods for cooking depending the altitude and the power available.

Cooking with Diesel:

The "Wallas" 85 Di diesel stove has a glass ceramic top

and is widely used in yachting. It has a high-altitude kit installed and works above 4500 m altitude. The stove can also be used as heater should the ordinary diesel heating fail. It has proven to work fantastic: Run it on the lowest level possible, place an empty frying pan on the plate and distribute the heat using a ventilator. This way the heating works for many hours with very low power consumption.

CAUTION:

The combustion air for the stove is taken from the living room. If all the windows are closed while heating one may run out of breathing air. The room must be flooded with fresh air every so often by opening the windows! In our case about every 4 hours. One must also make sure there is no exhaust gas entering the living room while sleeping (back-pressure into the exhaust through high winds or faulty installation). The installation of a CO-Alarm and a smoke-detector is absolutely mandatory!

Cooking with electricity:

If the battery is decently loaded we cook with 230V~ electric power. Most of the time this is the case. We carry a portable induction cooking plate which requires up to 2100 W of power.

The "Caso" S-Line 2100 induction plate only uses about 50% of the time to boil the same amount of water than an ordinary electrical plate. This is a reduction in power consumption of more than 50%. Of course, cooking pans must be bought for induction type stoves. The bottom of the pan must be magnetic.

In addition we have a "Caso" IMCG25 inverter microwave

/ grill / convection oven installed. This unit also requires about 2000 W of power. We cannot run more than one 230V~ cooking appliance at the same time without overloading the inverter. If we are hooked-up on a campsite it depends on the (adjustable) amount of external power we can draw. Fortunately, if there is too little external power available the "Mastervolt" inverter can deliver the rest.

Cooking with diesel and electricity eliminates the need of having

LPG gas or any other explosives on board which is a security measure.

A standard "Blanco" Lantos-IF household-grade kitchen sink was chosen

in favour of the sinks normally used in caravans due

to its wider drain system.

The fittings also are standard household types.

The faucet is a "Sonaqua" Japura 3in1. It has two valves and two outlets. One for the Carbon filtered cold and hot water and the other for the drinking water which is additionally UV-filtered. We never buy drinking water in bottles even if we use water from nature sources.

Under the kitchen table is the 60-litre fridge box from "Wemo"/ecetil EZC 60. It has a built-in Danfos compressor and works with either 12V= or 230V~.

It automatically switches to 230V~ if there is external power available. It never runs on inverter power.

While driving the kitchen area is used as additional storage for household and food items. Towel hangers abobe the sink are uased to dry towels and dishclothes.

At the front right side of the back-section is another huge

block of cabinets.

Above the Microwave drawer, shown further up as part of the kitchen, is the spices drawer.

Next to the right is the clothes and office compartment.

The big compartment on top, is mainly used to store guitars and other

bulky stuff.

The dimensions of the whole back-section have been adapted

to the measurements of the proven "Swiss

Rako-Boxes".

The boxes measure either 30 x 40 cm or 40 x 60 cm. Various heights are available.

Right of the clothes compartment is another row of such drawers. Each capable to carry a

load of 40 kg.

The top drawer holds food items in two separate boxes. Next below is the drawer containing the pans and the garbage bin.

The garbage bin box can be removed to be used outside the back-section. To be able to extract a full bag the purpose-built bag-holder can be removed.

The drawer below the rubbish bin is also subdivided in 2

boxes for easy access. The top one is removable. It holds dishes and cutlery.

The lower part is used for food storage.

The lowest drawer is used for even more food. We always carry food for about 4 weeks.

The table in the middle part of the living room is also one of our "inventions". It measures comfortably 81.5 x 70 cm excluding the extension.

It can be adjusted in height; can be shifted in all directions; can be tilted upwards for ease access to the storage area under the benches

and can even be removed completely if required. It is fixed to the wall

using the anchor rails and fittings originally designed

for the flight industry and which are common in European campers. All movement is blocked by one pin for transport.

The table is strong enough to be used as step into the bed when shifted fully backward during the night.

With the easy mountable extension the table measures 100 x 70 cm. 4 Person can easily be seated for diner.

2 people sit on the rear bench, 1 sits on the front chair and the poor cook sits on a cushion on the fold-up seat. Unfair but practical.

2018: To add more confort we bought an external PC-monitor. As monitor stand we use our shower wall which had to be slightly modified.

The same monitorcan also be fixed to the front wall to be used

as video screen.

An expandable "Leifheit" Rollfix 210 Longline clothes line can be used outdoors.

Flight-rails are used to mount the clothes

line. It can be adjusted in length according to the

amount of space required.

Indoors the same line can be stretched between the front and the back wall using pre-installed anchor points.

|

![]() Created by Level X Webdesign

Created by Level X Webdesign