The back-section

The back-section was built by Alu-Star,

in Murg, Germany.

It is based on an aluminium-sandwich construction normally

used for refrigerator trucks.

It is mounted on a steel-frame that acts as a sub-chassis

between the truck and the back-section. The frame is

fixed to the truck using OKA's standard bus body mounting

points and hardware.

Driver cab and back-section are riveted and glued together

to form one single unit.

2009: After a few years of travelling and quite some heavy off-roading it shows that the OKA chassis flexes much more as promised by OKA. Due to this the back-section shows some minor cracks. Additional rivets are used to further strengthen critical parts and an additional rubber damper is added to the all chassis mounts so the back-section can separate from the chassis more easily. The new spare wheel carrier has guides to stabilise the back-section sideways if it separates from the chassis.

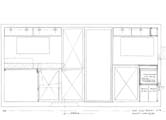

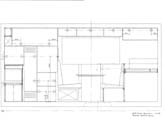

Layouts of the camper back-section

Left and right view

Inside layout from top, the left side, the right side

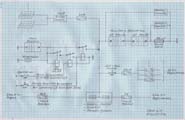

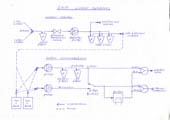

Electric, fresh-water and water-floor-heating system diagrams

Details of the camper back-section

The whole truck is quite small in size and very compact

taking into account its functionality.

It is 6.50 m long, 2.10 m wide and 3.25 m high. The track-width

is just marginally wider than the track-width of standard

4WD's.

The back-section is just 10 cm wider and a few cm longer

than the original OKA bus body.

The height however, is substantially higher than the

original OKA bus body to allow passengers to stand upright

in the camper.

The camper is also designed to be used in hot and very

cold areas (where temperatures fall below - 20°C).

Therefore a pop-top solution was unsuitable.

The inside of the camper is 3.83 m long, 1.94 m wide

and 1.84 m high.

2009: The back-section is fixed to the chassis using a steel frame and the original OKA mounts. After some years of travelling and heavy off-roading the back-section shows a few minor cracks. The chassis flexes much more then promised by OKA. Additional rivets are used to strengthen the back-section and an additional rubber ring is added to all mount points, so the back-section can easier separate from the chassis. Additional stabilizers are added to the new spare wheel carrier.

With hatches and window protection lids all closed

it looks more like a commercial truck.

This was done on purpose as if all goes well the truck

will be taken around the world in a few years and there

are areas where you don't want to be instantly recognised

as a tourist.

White was chosen as colour for the truck, not only because

of the heat reflection but also due to security reasons.

A light brown colour would have been better but the

truck could be mistaken as a military vehicle, which

is something we wanted to avoid if possible.

The back-section has windows on both sides and 2 skylights

in the roof can also be opened to allow the heat to

escape.

2012: Added "splash walls" allow the hatches to be opened 3 cm under all weather conditions. No water can penetrate under any weather condition.

Double glazed security glass windows are used for better

insulation. They can be locked at any angle.

2009: The possibility to lock the windows in any angle is removed. We have never used it.

The windows are covered by 3 mm aluminium lids for protection

against damage and for better security.

The lids also protect against sunlight and heat when

open while living in the camper and when closed while

driving.

Windows and protective lids are both opened and closed

from the inside the camper.

2013: The edges of the windows started to dismantle. They are now all reinforced.

2008: LEDs are fixed to all window frames and to the upper part of the door. They shine through the mozzie screens into the camper and spend enough light inside for living without turning on additional lights. Since the light source is outside the Camper the flying objects just fly to the mozzie screen and then turn around to reach the outside light. This enables us to always leave all windows open no matter the amount of flying annoyances. Even better the ones already inside try to leave the camper to get to the LEDs.

2010: To further improve the security on Roll-on Roll-off ferries the aluminium lids can now be bolted to the back-section from inside the back-section.

2008: Easy attachable and removable cloth triangles can be fixed to the upper part of the door as well as to all windows. This allows us to let door and windows open even if it rains. The feature used mainly in hot and humid regions. If the coth triangles are not used the same fixation can be used for a small clothes hanger which is also accessible from inside if the door is closed.

2010: Also to make the back-section more theft proof 2 bolts have been added to the door. It is now impossible to break in through the door even if the bolts of the hinges are forcibly removed.

Opening the hatches shows all the hidden details.

The space in the front hatch on the left side is taken

up mostly by the water installation and the water- and

floor heating-management.

It also houses the diesel stove and it´s fuel

tank.

The space in the back hatch is large and is subdivided.

The front section contains the "bicycle-garage",

housing 2 foldable full-size mountain bicycles.

Cargo in the section behind the bicycles can be accessed

from both sides of the truck.

The equipment mounted on the hatch is used for water

filling and filtration.

The water first passes a coarse filter, then a powerful

water pump (normally used to water the garden), followed

by 3 active carbon filters, which in this application

are only used to filter out any particles before entering

the water tanks using an attachable hose. This way the

tanks cannot silt up.

The pump is only switched on if there is no external

water pressure available, otherwise the water just passes

unhindered through the pump.

The floor of the water management area has been fitted

with a stainless-steel basin with direct drain tubes.

There is no way that fluids spilled in that area can

find their way into the inside of the back-section.

Drinking water is stored in 2 x 100 litre steel tanks

(the black, rubber-foam coated boxes in the picture

above).

Stainless-steel tanks were chosen to prevent the loss

of the water should the truck catch fire (for whatever

reason). The tanks have exits only at the top so the

tanks cannot leak.

The level of both freshwater tanks is monitored by water

gauges and the level is displayed on the "electronic

panel" inside the camper.

Potable running water is made available with a water

pump and an internal water pressure regulator.

After the pump the water passes a carbon filter and

an UV sterilizer for water purification before branching

to the 20 litre boiler and the cold water taps.

A silver wire is inserted in the warm water hose between

the boiler and the tap to reduce the risk of bacteriological

contamination. The hot water can be heated by either

240V~ power from the inverter or with hot water from

the motor's cooling system or the floor heating (whatever is active).

2008: We added another water pump and a y-tap. If we

are unable to get potable water for a longer time-period,

we can fill one tank with lower quality water (bore water).

After switching the y-tap, all water taps (sink, shower)

except the cold water tap on the kitchen sink deliver

now

bore water. The bore water bypasses all filters.

Next to the boiler (red) there is a 14 litre grey

water tank. It is just big enough for one day.

2010: The plumbing is changed to enable fresh water tank switching from inside the cab (not shown in the picture).

The diesel driven stove has its own 7 litre fuel tank,

which is filled from the left hand main diesel tank by

an electric pump. The overflow is redirected back into the left

diesel tank. This way, even if the left diesel tank

is empty, there is still fuel available for cooking.

Having this small diesel tank inside the cabin also

prevents the diesel from gelling with cold outside temperatures.

As the stove is known to be "a bit sensitive"

to dirty diesel, the diesel is passed through a separate

filter when pumped into the little tank.

2009: The pump to fill the Tank of the stove is "moved" to a different location in the System. This allows filling the small tank from the currently active main diesel tank. The overflow is redirected back in the currently active main tank. At the same time the pump can be used to bleed the OKA's fuel system. An OKA-NT has no bleeding system installed. If one runs a tank dry and air gets into the system it is nearly impossible to restart the truck.

2012: From the beginning we had infrequent problems with the diesel stove. If it wasn't used for a while it couldn't get started without touching "some" cable at the stove. The problem has not been encountered since we removed all critical plugs on the stove and replaced them with soldered connections.

The 2 full-size foldable mountain bikes have been modified

so they can be used for serious touring.

The smallest the mountain-bikes can be folded together

is 77 cm by 110 cm.

These were the base measurements that could not be changed

when the rest of the back-section was designed.

Also a large aluminium table (118 x 78 cm) is fitted

inside of the hatch lid.

4 people can comfortably eat at the table.

The other section goes right through the back of the

truck and can be used for long items.

The umbrella sunshade, its mount and lots of other

stuff can be found there.

The umbrella hangs on a "gallows" that is

fixed to a pair of anchor rails on the back-section.

It can be erected anywhere on either side of the truck.

The umbrella measures 3.25m x 2.5 m. Due to its size

it must be tied down under windy conditions.

A mozzie tent can be attached to it should there be any

flies around ....... :-) .

2007: The umbrella is unloaded. It is too windy in Australia, we have to reduce weight and we used it very seldom.

On the right hand side the hatch towards the front

contains the house batteries, fridge compressor, inverter,

tools and the large clothes-cabinet.

The clothes-cabinet is accessible from inside only.

The hatch towards the back contains recovery gear,

camping equipment, boogie boards and plastic (Rako) boxes

containing more tools, fluids, etc.

At the bottom of the compartment, under the clothes,

the inverter and the fridge compressor have been mounted.

Both take the cooling air from within the camper and

blow the warm air along the back of the clothes-compartment

and back into the camper. This keeps the clothes warm

and dry.

The fridge's cooling fluid can be refilled and also

the compressor replaced from the outside of the camper.

The two 6V, 300 Ah batteries chosen are designed for

industrial forklifts and should withstand quite some

punishment. Nevertheless they are shock mounted.

2009: The batteries are replaced by 2 AGM 6V blocks of 380 Ah. Beside the fact that they are maintenance free and do not leak when we tilt the truck, they have more power and are smaller and lighter. What else could you ask for!

2010: The American continent generates its own problems regarding the electrical system: Mainly in the southern part of South America the efficiency of the solar panels is reduced due to the angle of the sun. At the same time the energy consumption rises because of the low temperatures and because of partially extreme altitudes where we will have to cook with our electric cooking plate (we still have no gas). Also some countries (like USA) do not use 220 - 240V mains voltage and as consequence our battery charger will not work. To overcome all this problems and to stay independent we decided to buy an EFOY 2200 fuel cell which should be capable to cope with the shortfall of electrical energy. The fuel cell as well as its Methanol tank are installed above the inverter in the clothes cabinet.

2012: The EFOY is a good thing but is by far not as strong as we expected. This is my own fault. Generators are all labelled by the numbers of Watt they produce. Unfortunately I didn't know the difference between Watt (W) and Watt-hour (Wh). Instead of being able to drive a cooking plate with 2000W (EFOY2200) it is only capable to drive an appliance with roughly 90W (2200W/24h=91.6Wh). This is about as much as a Laptop power supply! And it weighs about 20 kg and sets you back by a few thousand dollars! Additionally the EFOY requires medical quality Ethanol which is most possibly not available in South-America. The EFOY has been removed. If we really need more power we will again buy a power generator.

The electricity is normally generated by eight 55W,

12V= solar panels mounted on the roof of the camper.

The panels cannot be tilted.

The solar controller can cope with a charge rate of

up to 40 Amps.

2014: On slightly overcast days the solar controller lifts the battery voltage, without significantly loading the batteries, to a level where also the alternator stops charging.

To avoid this symptom the solar panels can now be switched off using a battery separator switch.

The batteries in the back-section are charged either

by the solar panels, the dual battery system driven

by the OKA´s alternator, or by the battery charger

using external 240V~ external Power.

The 1300W pure sine wave inverter also incorporates

a 55W battery charger and a 240V~ 16A power transfer

system.

The inverter is powerful enough to run equipment such

as electric 240V~ chain saw, drill, angle grinder, vacuum

cleaner etc.

The hatch towards the back of the camper holds almost

all of the recovery gear, the "bigger" tools,

two boogie boards and all the hiking gear which includes

backpacks, tent, sleeping bags, self-inflating mattresses,

cooking gear etc.

An expandable aluminium ladder which unfolds to 3.05

m in length is also stored here.

Its collapsed length is only 78 cm.

On the back of the back-section are a light bar with

two 55W reversing lights and a small crane arm with

the reversing camera.

The crane arm can be used with a chain block to lower

spare wheels.

The spare wheels were originally mounted to the back

wall, but the carrier was too heavy and had to be removed.

The original location for the spare wheel underneath

the back of the OKA destroys the excellent departure

angle and eventually the wheels will get mounted onto

the back wall again.

2009: we build a new and lighter spare wheel carrier which also carried the 6 fibre glass sand boards. The second spare tyre is still on the roof rack.

If the temperature gets too cold, a warm water under

floor heating system keeps the inside very cosy.

The main advantage of floor heating is that it avoids

the common "cold feet and hot head" feeling

typical of air heaters.

Since the heating tubes run along the whole floor, there

should be no cold spots (less condensation), frozen

water pipes or "solidified" diesel in the

tank for the stove. This is important for very cold

European winters.

The heating is driven by a warm water heater normally

used to pre-heat truck motors.

The heating system is also connected to the warm water

boiler and to OKA's motor cooling system. This allows

the floor-heating and the warm water boiler to be heated

with the OKA's motor cooling system.

It also allows pre-heating of the motor in the morning

by using the warm water from the floor heating.

The diesel heater sits between left front wheel and

left diesel tank, from where it also gets the diesel.

The protecting cover has been removed for the photo.

The control valves for the heating are under the kitchen

sink.

2010: The floor heating is great but it needs a long time to heat up the cab once it is cold. To speed up things we add an "Eberspaecher Helios 2000" heater blower to the system. It also uses the hot water of the floor heating as heat source and turns on automatically as soon as the water reaches 30°C. The cold cab now reaches the set temperature within 4 minutes. The heater blower is placed under the rear bench. To be able to use the diesel heating at higher altitudes we install the "Eberspaecher high altitude kit".

2011: The heater blower is too fast in heating up the cabin. The Eberspaecher requires a heating cycle of at least 10 minutes. The relays that starts the blower when reaching a water temperature of 30° is replaces by a Hella time delay relay which delays the blower start by 8 minutes.

2014: Heating the cabin with the motor is very difficult to properly adjust. Either the temperature gets far too hot or stays too cold. We modify the heating control so the Eberspaecher thermostat can now be used to control a valve in the water pipes that shuts down the heating when a set cabin temperature is reached (see the diagram further up). Now the heating is perfect - day and night and at any outside temperature.

Inside the camper most appliances and power outlets

are 12 V=. Exceptions are three 240V~ outlets, the UV-water

purifier and the water pump used for water intake from

a billabong or river. The hot water system also has

the option of 240V~ heating as well as the engine or

diesel described above.

The 240V~ plug system used is the Swiss one. It is a

safer system than its Australian counterpart as the

power only flows once the plug is completely inserted

into the socket.

The lights are a mix of fluorescent and halogen.

All main 12V= and 240V~ circuits are secured by circuit

breakers. The 240V~ circuit also with a RCD (residual current

device).

Funnily enough the system didn't get certified for

Australia because of the installed Swiss connectors

which would be acceptable for tourists, but not for

residents.

It really doesn't matter as the campgrounds that should

check the certificate never do so. Beside that we never

use powered sites anyway as we are fully self-sufficient.

The electric panel at the front of the back-section

contains from left to right:

- Battery charger-inverter control panel

- Diesel stove controls

- iPod and radio

- Water tank level display

- Battery consumption and load monitor

- 12V= circuit breakers

- Fridge control

- Smoke detector (underneath the panel)

2010: The control panel for the EFOX 2200 fuel cell has been added.

The sound system consists of a car stereo system driving

a 3-way speaker system.

An additional interface allows an iPod to be connected

to the system. The 30 GB MP3-files are the main

music source out bush.

The speaker cases are custom built.

There is a second interface in the driver's cabin thus

allowing the same iPod to be used in the back-section

and up front.

2010: To be informed about the major events in the world we buy a "Sangean ATS 505" short-wave receiver. Since "ABC Radio Australia" only transmits into the Asian area, it cannot be heard elsewhere in the world. So we depend on Great Britain's "BBC World Service". Also a TV antenna has been added; even so we only use it very rarely.

2013: In South-America the short-wave receiver is not of much use so far. The German news transmitter "Deutsche Welle" stopped sending in 2012 and neither "BBC World Radio" nor "Voice of America" transmit to South-America. These days all international information services are using Internet or satellite radio.

There are various alarm systems in use.

Inside the camper a narcotic gas alarm combined with

a CO warning can be activated.

An ultrasound intrusion detector and various door switches

could be added to the system if needed.

The driver cab is ultrasonic protected.

Also a smoke detector is used inside during the night.

2013: The CO-detector can now be switched off. Some washing detergent used to wash the bed linen can activate the alarm for a few days :-))

Outside the camper another detachable smoke detector

is used when camping out bush where bush fire could

be a threat.

Sleeping people don't smell smoke and don't notice an

approaching fire and therefore cannot react by escaping

on time.

The large windows are excellent for efficient ventilation

even with low wind. Besides that they allow an excellent

view of the country outside.

2008: There is no air condition in the back-section. To increase airflow in hot areas an additional, removable blower is installed.

They have mozzy screens mounted with Velcro in a "cloth

frame". This allows easy replacement if damaged

and also allows different types of mozzy screens to

be fitted.

The cloth frame itself is also fixed to the window frame

using Velcro so it can be completely removed.

Blinds are installed inside instead of ordinary curtains.

They shut better and are less exposed to sunlight when

not in use.

The two 85 cm x 50 cm wide roof hatches consist of

an aluminium frame holding a 10 mm transparent polycarbonate

plate.

They are hinged on one side, can be fixed in 4 different

opening positions and can also be fully opened to give

access to the roof.

If required steel plates can be fixed inside the hatches

for better theft protection while the truck is on a

ferry boat.

Also inside the hatches there are hinged aluminium

fly screens to protect against most of the well-known

"beasts".

Meanwhile we also found a satisfying solution to the tiny flying

objects that crawl through the mesh as soon as you turn

on the light inside the camper.

We installed LED-lights at the lower bar of the window frames. When the windows are opened, the lights swing out together with the window, so the light source is outside of the camper. The beasts try as usual to fly towards the light source - away from the camper, not into it. This way

we have enough light inside the cabin but if we really

want to use the inner lights we still have to close the windows.

The mozzie screen door is a "can do everything"

gismo and was very difficult to build.

It can be closed, fully opened as a fixed door or folded

away.

It can also be closed with the lower part or both parts

of the main door closed. By doing so, the door handles

and the lock must pass through the mozzy door, so these

holes have badger hair brushes fitted which close them

tightly.

The mesh used is aluminium and can be easily replaced.

The floor of the entry section is a 70 cm x 70 cm wide

shower pan, which also acts as a "wet and dirt"

entry area.

The shower pan is only 3 cm deep and covered by a perforated

checker-plate aluminium sheet. The tray has 4 outlets, one

in each corner, thus allowing the water to drain even

if the truck is not level.

A 15 cm high side wall can be temporarily fitted to

prevent the shower curtain from moving outside the pan

when showering.

The shower hose can be detached and can also be used

when showering outside using the shower solar heated

bag.

2009: The new cloth hanger is used for wet clothes. If not used the hanger disappears into the aluminium profile of the overhead compartment in the kitchen.

All cabinets have a sturdy aluminium frame covered

with aluminium-plastic-aluminium sandwich walls and

doors.

This eliminates the need for any wood in the whole camper

which is an advantage under humid conditions where wood

could swell. On the downside, the humidity inside the

camper is not absorbed anywhere and condensation is

more difficult to control and can be a problem.

All doors and walls are bolted to their frame and can

easily be removed to give access to about any place

in the camper.

This is very handy in case of repairs or when installing

add-ons.

The same sturdy fittings are used on all doors including

the fridge.

At the right side of the entry is a whole block of cabinets

(left side of the camper).

One cabinet on the top row holds clothes on hangers

and the other various household items as well as the

CO2 fire extinguisher and the fire blanket.

The middle cabinet was built for all our shoes.

The right bottom cabinet is used for various things

that have to be accessible from outside.

The other one hides the chemical toilet during the

day. During the night the toilet stands in the entry

in the shower pan.

As the head part of the bed is behind the cabinet, there

is privacy when using the toilet during the night.

The bed in the back of the camper consists of a slatted

aluminium frame which collapses to half of its width

during daytime. The expanded bed measures 194 cm x 140

cm and it is possible to sit on the bed without hitting

your head on the roof.

The front border of the collapsed bed serves as the

upper part of the back rest of the long bench.

Collapsing and expanding the bed takes less than half

a minute.

Premium quality foam mattresses are used as well as

standard linen.

Very comfy!

Windows on both ends of the bed and a hatch above it

guarantee excellent ventilation.

The kitchen is spacious because the areas are used

several times: for the stove, as work space and for

the drain board.

The stove used for cooking has a glass ceramic top

and is widely used in yachting.

It runs on diesel. This eliminates the need of having

LPG gas or any other explosives on board which is a

simple security measure.

2010: The Wallas diesel stove only works to an altitude of 2000 - 2500 m. In South America we will exceed this by far. To overcome the problem we bought a 1500W electric cooking plate. It runs from our batteries and the installed inverter is just able to cope with the load. Soon it proofs to be very handy for short cooking sessions.

2014: The Wallas diesel stove is the worst piece of equipment we have installed so far. Since the beginning we fight start-up problems mainly based on lousy electrical connections, failing relays and broken transistors. Meanwhile all connectors have been replaced by soldering the wires directly to the PC-boards. Main culprit is the area around the glow-plug which is used to start the combustion. Once the combustion has started the Wallas always works fine. We now installed a push-button

that allows us to directly applies 12V= to the glow plug as long as it is needed for the start-up. So far the Wallas starts very well and starts combustion within 1 minute.

2011 / 2012: The electric cooking plate was too strong. In South-Africa we burnt our inverter. We now replaced the electric cooking plate by an induction cooking plate with max. 2000W. In position 5 it only uses constant 1200W. In position 1 - 4 it also uses 1200W but periodically switches on and of (the same way as the electric cooking plates work). The positions 6 - 9 (14000W - 2000W) can only be used when we are connected to external power. But also in position 5 the induction plate only uses 50% of the time to boil the same amount of water than the electrical plate used to. This is a reduction in power consumption of more than 50%. Of course new cooking pans have to be bought for induction type cooker. The bottom of the pan must be magnetic.

A standard household-grade kitchen sink was chosen

in favour of the sinks normally used in caravans due

to its wider drain system.

Also the fittings are standard household ones.

At the front right side of the camper is another huge

block of cabinets mainly to store kitchenware, food

and beverages.

The 78 litre stainless steel fridge without deep freezer

is driven by an external compressor.

For the temperature-management a special controller

has been built in. It cools the fridge down by an additional

5°C when the vehicle's electrical voltage is sufficiently

high.

The clothes in the cabinet are kept free of mildew

by the warm air from the fridge compressor forced to

travel upwards through the cabinet.

The big compartment above fridge, clothing cabinet

and drawer is mainly designed to store guitars and other

musical instruments.

The inner dimensions of the camper have been adapted

to the measurements of the proven plastic "Swiss

Rako-Boxes". Each of the drawers could carry a

load of 120 kg.

Of course the kitchen wouldn't be complete without

the rubbish bin. The bin is built into one of the Rako-Boxes. The box can be removed from its cabinet and used outside.

To be able to remove a full bag, the bag can be removed

including its fixation and closing lid.

The drawer below the rubbish bin is subdivided in 2

boxes for easy access.

The cooking pans are of the type used for electrical

ceramic stoves.

A lot of spices are an indication of good tucker ....

The spice drawer can be tilted upwards to give access

to another Rako storage box which sits on top of the

two steel water tanks.

Both the drawer and the Rako box can be easily removed

to give access to the escape door which connects the

back-section and the driver's cab. The escape door can

only be opened from the camper back-section.

The table in the middle part of the camper has a Corian

table top. It measures 72 x 82 cm.

It can be shifted sideways and blocked for transport;

it can be adjusted in height; can be tilted upwards

to ease access to the storage area under the benches

and can be removed completely. It is fixed to the wall

using the anchor rails and fittings originally designed

for the flight industry and common in European campers.

The table can be extended to 72 x 100 cm to comfortably seat 4 adults,

3 on the fixed seats and one on an additional chair.

2007: At the side of the front bench a fixed foldable seat is added for the 4th person.

2010: The shape of the table extension is too cumbersome, it's handling painstaking. We decide to change the sliding mechanism of the table so it can be shifted front to back (as before) as well as sideways. The table extension is now inserted at the wall end. It is now smaller and lighter. Still the table is strong enough to be used as step into the bed when shifted fully backward during the night.

An expandable clothe line can be used outdoors or indoors.

Outdoors the anchor-rails are used to mount the clothe

line. It can be adjusted in length according to the

amount of space required.

Indoors the line is stretched between a mount that usually

is hidden by the rug on the wall and the towel holder.

If the clothe line is used indoors e.g. to dry some

clothes while driving, the OKA cabin air condition can

be used to dry the clothes.

For more serious repairs a strong vice is part of the

extensive set of tools. It can be attached to both sides

of the bull bar. Since the inverter delivers up to 1300W,

standard drills, angle grinders and the like may be

used together with air driven tools such as rattle guns,

metal saws etc. |

![]() Created by Level X Webdesign

Created by Level X Webdesign